A male connector is a type of hardware component designed to fit into a corresponding female connector, forming a secure and reliable connection.

What Is a Male Connector?

A male connector is a hardware component specifically designed to establish a secure connection by fitting into a corresponding female connector. It is characterized by its protruding elements, such as pins, prongs, or threaded ends, which are engineered to align and interface with the receiving components of a female counterpart.

Male connectors are commonly used across various industries, including electronics, plumbing, and mechanical systems, to enable the seamless transmission of signals, power, data, or fluids. The design ensures precise alignment, efficient functionality, and durability, making them an integral part of connection systems. The materials, dimensions, and configurations of male connectors are often tailored to the specific requirements of their applications, ensuring compatibility and performance in diverse operational environments.

What Is a Male Connector Used For?

A male connector is used to establish a physical and functional connection between components, enabling the transfer of signals, power, fluids, or data. It is designed to fit into a corresponding female connector, forming a secure link that ensures reliable operation in various applications.

In electronics, male connectors are commonly used to transmit electrical signals or power between devices, such as plugging cables into ports. In plumbing, they facilitate the flow of water or other fluids by connecting pipes or fittings. In mechanical systems, male connectors are utilized for joining components to ensure structural integrity and proper alignment. Their precise design and compatibility are critical for maintaining efficiency and safety in these systems.

Male Connector Types

Male connectors come in various forms, each tailored for specific industries and applications. Their design varies depending on the medium being transmitted—whether it’s electrical signals, fluids, or mechanical force. Below are the key types of male connectors and their uses:

- Plug connectors. Plug connectors are commonly used in electronics and electrical systems. They feature exposed prongs or pins that fit into corresponding female sockets, enabling the transmission of electrical power or signals. Examples include USB plugs, power plugs, and audio jack connectors.

- Threaded male connectors. These connectors are widely used in plumbing and mechanical systems. Featuring external threads, they screw into female connectors with internal threads to create a tight seal. Applications include pipe fittings, hydraulic systems, and gas lines.

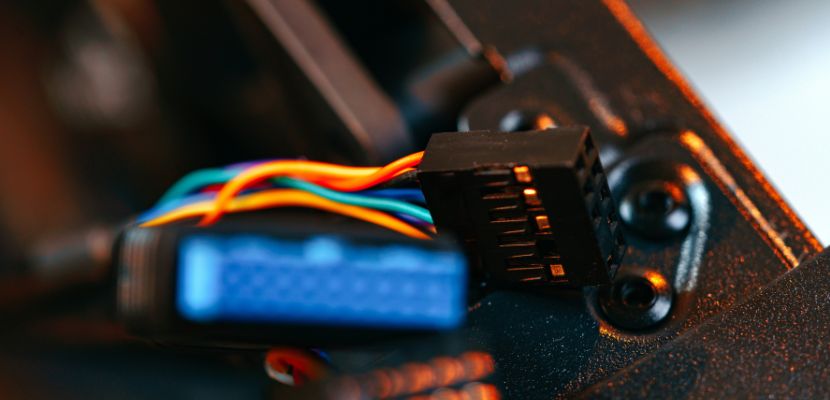

- Pin connectors. Pin connectors are designed for electronic circuits and data transmission. They consist of one or more pins that align with holes in female connectors. They are essential in devices like circuit boards, industrial machinery, and communication equipment.

- Quick-connect male couplings. Quick-connect male couplings are designed for fast and secure connections, often used in pneumatic or hydraulic systems. They typically involve a push-fit mechanism to attach to female couplings, ensuring efficiency in applications requiring frequent assembly and disassembly.

- Bayonet connectors. Bayonet male connectors use a twist-and-lock mechanism to create a secure connection. They are commonly found in lighting systems, military-grade equipment, and certain audio/video interfaces.

- RF male connectors. Radio frequency male connectors are specialized for high-frequency signal transmission in communication systems. They feature a central pin and an outer conductive casing, ensuring minimal signal loss in applications like antennas, cable TV, and satellite systems.

- Compression male fittings. These are used in plumbing and gas systems to create a secure, leak-proof seal. Compression fittings are ideal for applications where durability and high-pressure resistance are essential.

Advantages of Male Connectors

Male connectors are an essential component in many industries, offering practical and functional benefits in connecting devices, systems, and components. Their design ensures reliability, compatibility, and ease of use in various applications. Below are the key advantages of male connectors:

- Ease of connection. Male connectors are straightforward to use, designed to fit seamlessly into their female counterparts. This simplicity reduces assembly time and minimizes the likelihood of connection errors, making them ideal for both professionals and everyday users.

- Durability and reliability. Constructed from robust materials like metal or high-quality plastics, male connectors are built to withstand wear and tear, frequent use, and exposure to environmental factors. This ensures long-term reliability, even in demanding conditions.

- Versatility. Male connectors are available in a wide range of designs to accommodate various applications, including electrical systems, plumbing, and mechanical connections. Their adaptability makes them suitable for diverse industries, from consumer electronics to industrial equipment.

- Compact design. The streamlined and compact design of male connectors allows them to be easily integrated into devices and systems without occupying excessive space. This is especially beneficial in electronics and other applications where space is limited.

- Secure connections. Male connectors are engineered to form tight, secure connections when paired with their female counterparts. This ensures stable transmission of signals, power, or fluids, reducing the risk of disconnections or leaks during operation.

- Compatibility. Standardized male connectors are designed to work seamlessly with corresponding female connectors, ensuring universal compatibility within specific systems. This consistency simplifies replacements, upgrades, and maintenance.

- Ease of replacement and maintenance. Male connectors are easy to replace or maintain, as they can be detached and reconnected without specialized tools. This convenience reduces downtime and maintenance costs in various applications.

Disadvantages of Male Connectors

While male connectors are essential components in various systems, their design and usage come with certain drawbacks that may impact their performance and applicability. Below are the key disadvantages of male connectors:

- Exposure to damage. The protruding pins or prongs of male connectors are susceptible to bending, breaking, or corrosion. This can compromise the connector's functionality and require frequent maintenance or replacement, especially in high-traffic or harsh environments.

- Increased risk of electrical shorts. In electrical applications, the exposed design of male connectors increases the risk of accidental contact, leading to potential electrical shorts or shocks if not handled properly or protected by safety measures.

- Alignment challenges. Male connectors often require precise alignment with their female counterparts for a proper connection. Misalignment can cause wear and tear, damage to the connectors, or failure to establish a secure link.

- Limited dust and water resistance. Without additional protective features, male connectors are often less resistant to dust, water, and other contaminants compared to enclosed designs. This can limit their effectiveness in outdoor or industrial applications.

- Dependency on female counterparts. Male connectors cannot function independently and are entirely reliant on their compatibility with female connectors. Variations in standards or tolerances between manufacturers can lead to connection issues or reduced performance.

- Potential for wear during repeated use. Frequent insertion and removal of male connectors can cause wear on the prongs or pins, reducing their reliability over time. This is especially problematic in applications requiring repeated connections.

Male Connector FAQ

Here are the answers to the most commonly asked questions about male connectors.

Is a Male Connector Positive or Negative?

A male connector is neither inherently positive nor negative; its designation refers to its physical structure rather than its electrical polarity. In electrical systems, polarity is determined by the current or voltage being transmitted, not the connector's gender.

Male connectors feature protruding elements, such as pins or prongs, designed to fit into female connectors, which have corresponding receptacles. The actual polarity (positive or negative) of the connection depends on how the connectors are wired within the system. For example, in a DC circuit, a male connector could carry either the positive or negative terminal depending on the design of the device or cable.

Can Any Male Connector Be Used with Any Female Connector?

No, a male connector cannot be used with any female connector. Male and female connectors must be specifically designed to be compatible in terms of size, shape, configuration, and function. Compatibility is determined by standards and specifications set for each connector type, such as electrical voltage ratings, thread types, or pin configurations.

Using incompatible connectors can result in poor connections, damage to the components, or even safety hazards. Additionally, some connectors are designed for specific industries or applications, such as RF, plumbing, or data transmission, further limiting their interchangeability. Proper selection and matching of male and female connectors are essential to ensure functionality, reliability, and safety.

How to Choose the Right Male Connector?

Choosing the right male connector requires careful consideration of several factors to ensure compatibility, reliability, and safety for the intended application. Start by identifying the type of connection required, such as electrical, fluid, or mechanical, and select a connector specifically designed for that purpose. Ensure that the male connector matches the size, shape, and configuration of the corresponding female connector, adhering to industry standards or manufacturer specifications.

Evaluate the connector’s material and durability to ensure it can withstand environmental conditions, such as temperature, moisture, or mechanical stress. Consider the voltage, current, or pressure ratings to avoid overloading or failure. Additionally, take into account the frequency of use; connectors subjected to frequent connections and disconnections should be robust and resistant to wear.